1.Independent design, R&D, and manufacturing, ensuring stable performance and reliable quality.

2.All machine components are customizable based on the customer's budget, allowing for flexible configurations without compromising quality.

3.All parts are directly sourced and processed in-house, which reduces production costs while maintaining high standards—making our machines more competitive in price.

4.30 years of manufacturing experience as a direct factory; we offer comprehensive after-sales support to ensure worry-free operation after purchase.

IBR roof sheet machine/Trapezoidal panel forming equipment can produce roof panels with different peak numbers, thicknesses and widths. This time we mainly introduce the IBR roof sheet machine with an effective width of 760/762mm. This size is very popular in the South African market. At the same time, we can also provide different machines according to your requirements.

| No. | Item | Description |

| 1 | Production Capacity | 15-35M/MIN |

| 2 | Thickness | 0.4-0.8mm Thickness |

| 3 | Brand Name | XINNUO |

| 5 | Usage | Steel Construction |

| 6 | Rows | 13-18 rows |

| 7 | Effective Cover Width | 760/762mm or as your required |

| 8 | Overall Width | as your required |

| 9 | Raw Material | Steel plate、PPGI、PPGL,etc. |

| 10 | Cutting Blade Material | Gcr12 molybdenum vanadium blade |

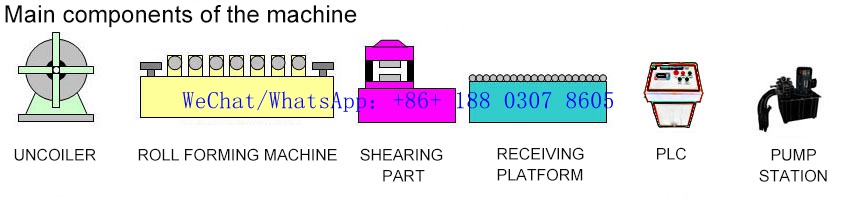

| 11 | Core Components | motor, Gear, Pump, PLC |

| 12 | Control System | PLC(imported Brand) |

| 13 | Decoiler | 5T Manual Decoiler or as your required |

| 14 | Packaging Details | Main machine is nude in the container, the computer control box is packed with wooden packaging. |

| 15 | Video Outgoing-Inspection | Provided |

| 16 | Place of Origin | Hebei, China |

| 17 | Port | Tianjin Port |

| 18 | Selling Units | Single item |

| 19 | Certificate | CE/ISO/TUV |

Xinnuo Roll Forming Machine is a professional cold-rolled forming equipment manufacturer with a history of more than 30 years. Its main products include purlin forming machines, roof and wall panel forming machines, sandwich panel forming machines, etc. The company has a strong design and development team and a complete after-sales service system. It has obtained many national patents and its products are exported to more than 150 countries and regions, and are deeply trusted and praised by customers around the world.